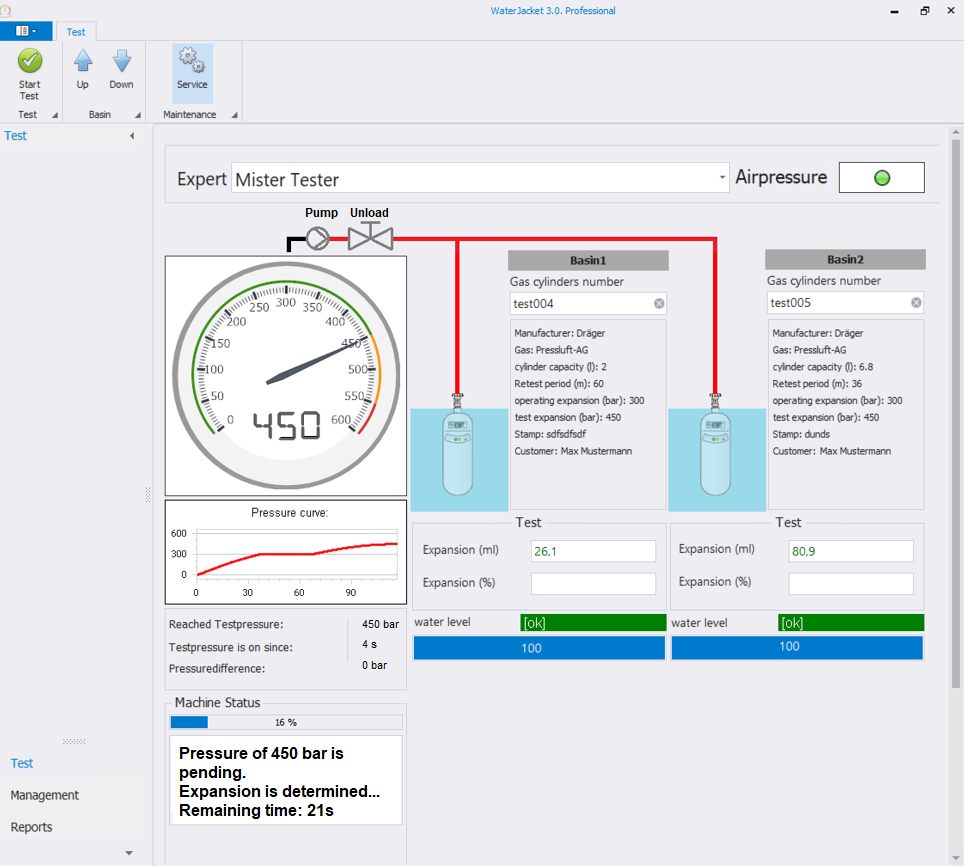

The 3rd generation water jacket testing systems

The new 3rd generation water jacket testing systems sign out through extremely quick and highly accurate measurement result, as well as many further optimizations. This is amongst other things achieved using highly modern PLC-Components. Depending on the version and features, the test process is carried semi-automatically or fully automatically.

Global data of the 3rd generation water jacket testing systems

- Test basin sizes according to customer wishes 2, 6, 6.8 und 9 litre bottles

- Test duration of two 6.8 litre cylinders in under 4 minutes

- Cylinder specific changeable and thermodynamic isolated basins for the minimization of temperature affects, which will affect the measurement results

- According to the configuration of the test basins it is possible to test two composite cylinders of the same or different size at the same time

- Modular built (technical unit and test unit), gradually expandable by two basins if necessary

- determination of the volumetric extension in ml respectively tenth ml

- Test pressure up to 450 bar (600 bar optional)

- Modules executed in stainless steel/alloy/polyamide

- Measurement data recording and machine control by PLC

- Controlled via Windows© Touch Panel Industrial PC

- Optional voice guidance for the test process and results

- Software side visualisation of the test process

- Multilingualism “German“ “English“ and “Polish“ further languages possible by agreement

- Local database for the management of gas cylinders (customer specifications possible)

- Possible connection to a central gas cylinder database (optional)

- Cylinder labelling and input via barcode label and barcode scanner (optional)

- Customizable selective test/result report (selection by customer, day, etc.)

- Remote maintenance possibility for the systems via RJ45

- Mechanical & software-based security features

- Connect a calibrateable scale to determine the weight of the cylinders

- Extensible and customizable hardware & software